ITALIAN FLUID MACHINES

Born with a legacy of tradition

and a drive for innovation

ABOUT US

After more than 20 years working with Liquid Ring Compressors, in 2022 a group of engineers decided to start a new company with a strong drive for innovation.

New manufacturing technics allowed innovation in design unthinkable just a few years before.

They knew it was time to develop a new generation of liquid ring compressors and fluid machines.

The result is Italian Fluid Machines, born with a legacy of tradition and a drive for innovation.

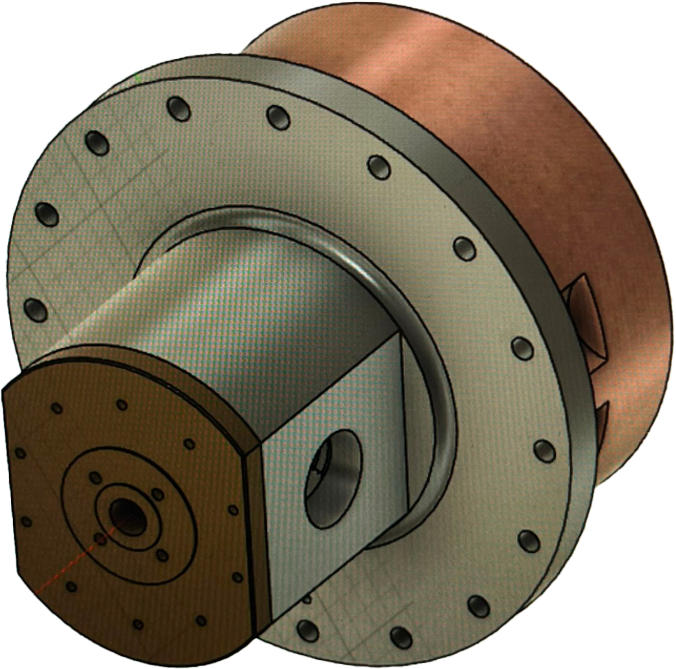

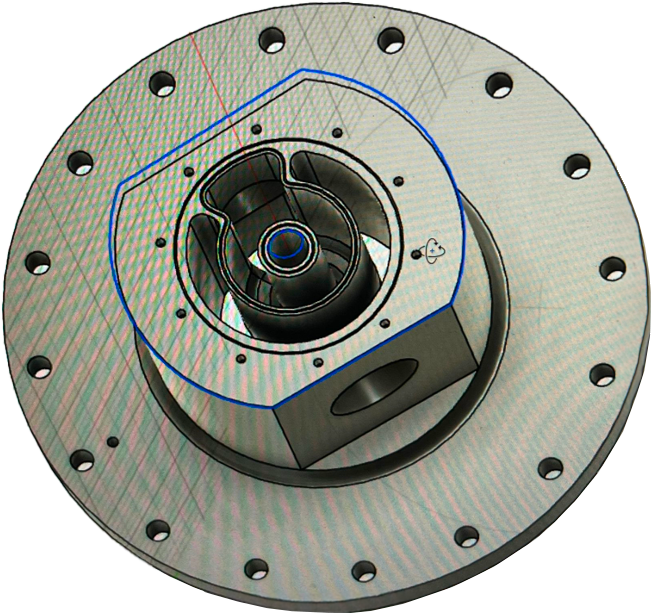

PRODUCT

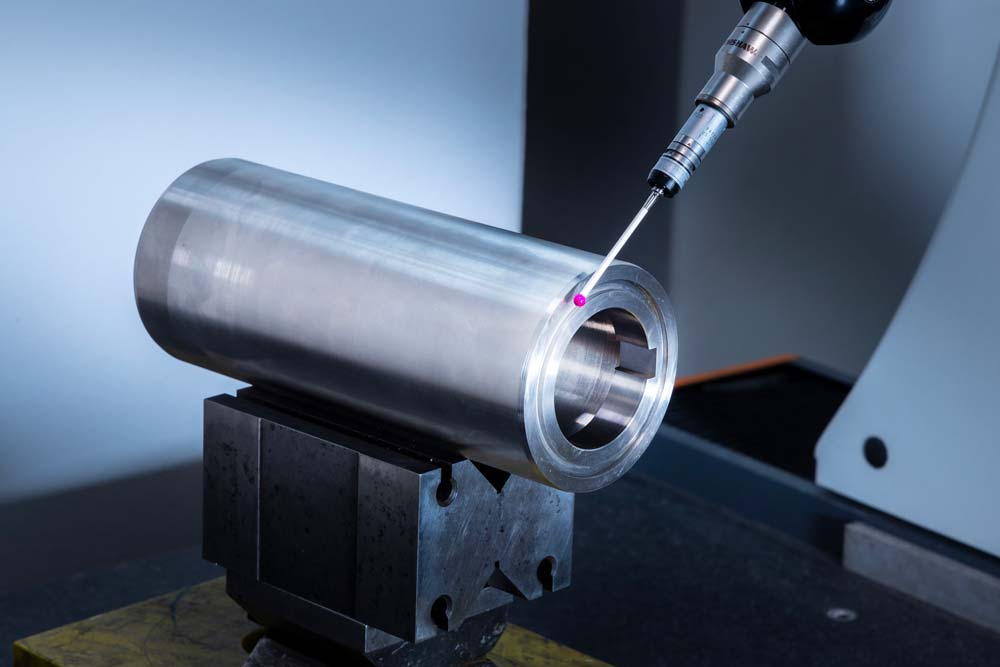

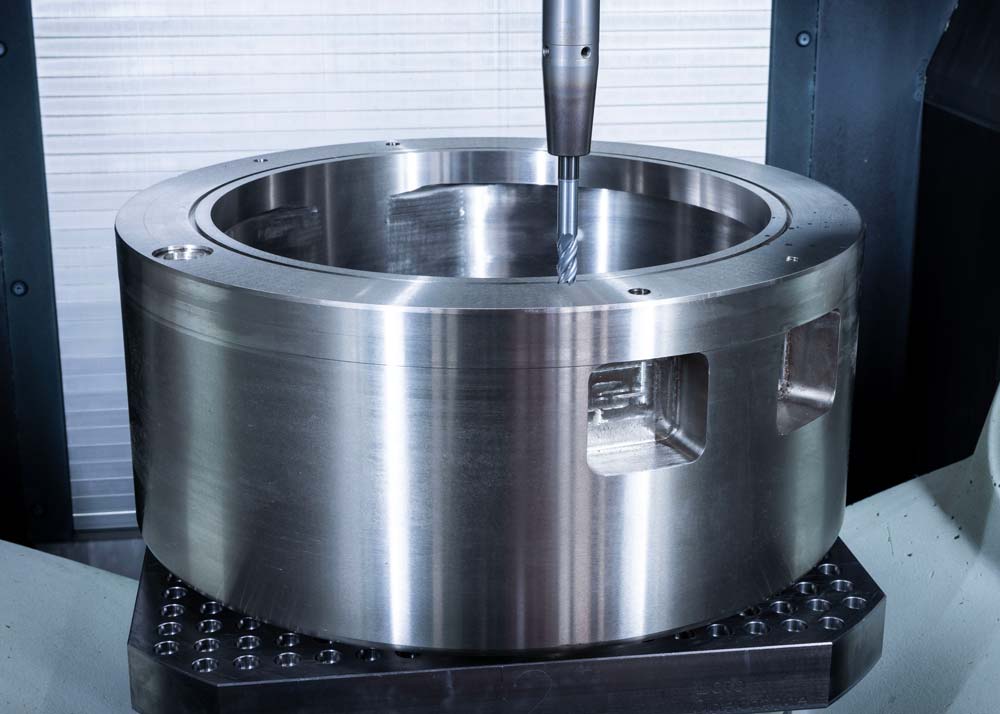

Our compressors are optimized through detailed fluid dynamic studies. Thinking about production technology since the design stage, and utilizing the latest forging and 5 axis milling 3D technologies, we are able to eliminate stagnation pockets, design and manufacture our impellers with variable blade profiles, optimized for the specific application.

IFM compressors are available as single stage, double stage or Progressive Compression Ratio (PCR) for special applications.

This means increased lifespan and better efficiency.

STATE OF THE ART DESIGN

- Casing with Double Eccentricity – Allows for perfect balancing of radial forces on the rotor.

- Overhung Impeller – Requires only one mechanical seal, reduces maintenance needs and time

- Front Pull Out – Reduced maintenance.

- Conical Distribution – The circulation of the seal liquid is by pressure differential – No recirculation pump is required.

- Axial Regulation of the Rotor – Easy check and adjustment of the impeller clearance.

- Tailor Made Design – Optimized efficiency and performance through modifications to the conical distributor, casing and impeller.

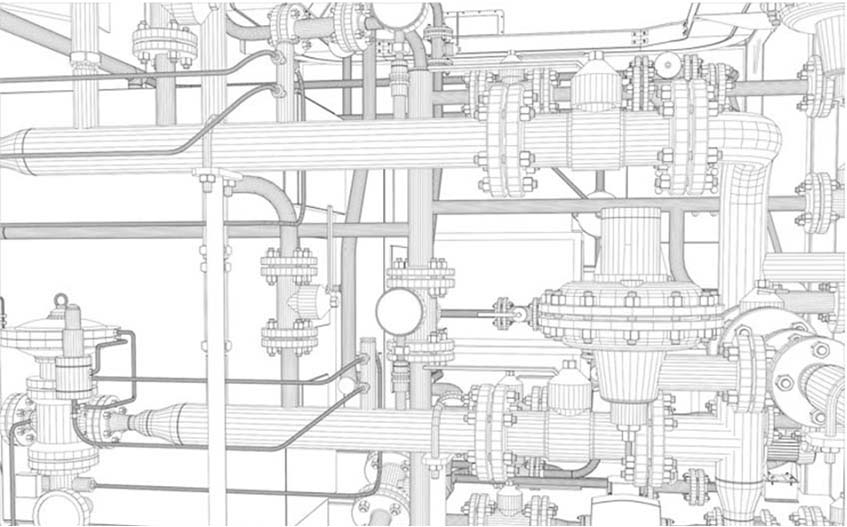

COMPLETE COMPRESSION SYSTEMS

- We design and manufacture complete compression and vacuum systems, skid mounted, for industrial applications:

- Flare gas recovery systems

- VOC recovery

- Chlorine compression

- VCM and other petrochemicals (pe, pp, etc)

- We include instrumentation, automation and control within our packages at request

- We design according to international norms or customer specifications. Our flexibility is our strength

PROCESS ENGINEERING

PROCESS ENGINEERING

SERVICES

- reverse engineering

- aftermarket and OEM parts

- compressor repairs and upgrades

- process simulations and engineering

- piping design and manufacturing

- pressure vessels design and manufacturing

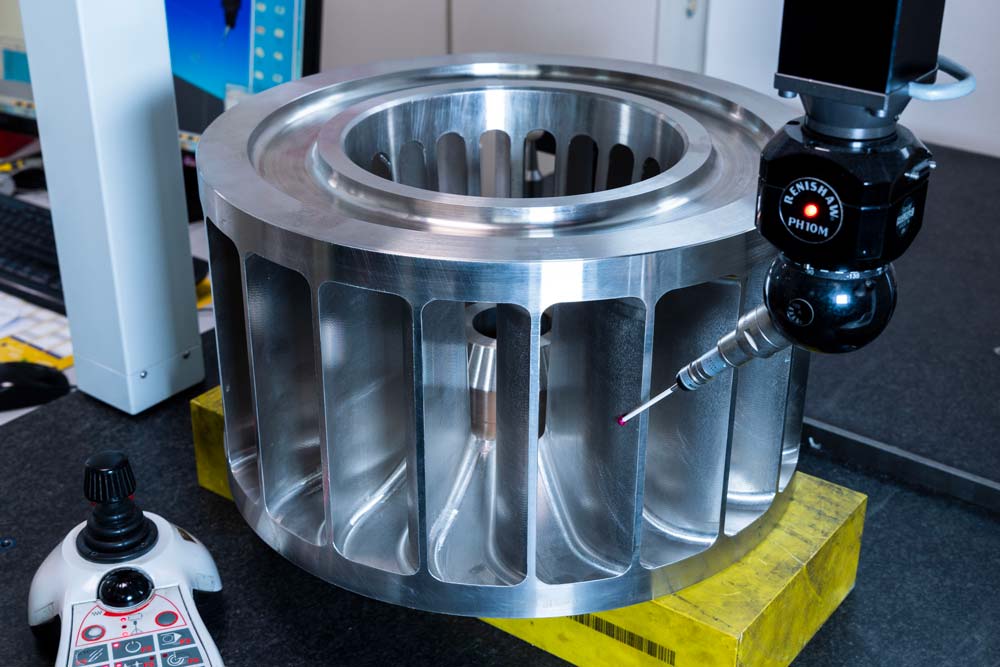

AFTERMARKET PARTS

We supply interchangeable spare parts for main Liquid Ring compressors brands.

We offer improved design and manufacturing technology for replacement parts, advanced quality, better materials and lower costs.

All parts made from Solid Forgings:

- stronger compared to cast OEM parts

- Optimized stress areas for additional durability

- machining technology delivers impressive finish and accuracy, eliminates stagnation pockets, optimise blades profiles

- Made in Italy

- Unmatched 100% interchangeability warranty

- Superior Quality

- Critical machine components are stocked at our warehouse to prevent costly production downtime

- Ask about your model availability

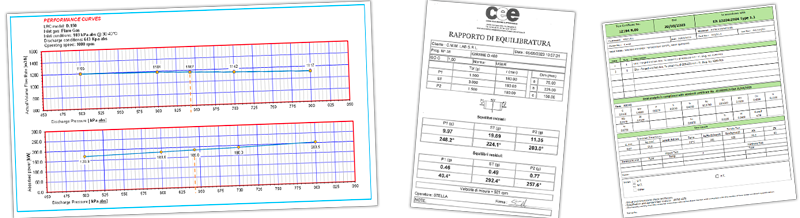

DOCUMENTED QUALITY & TEST

- Material certificates

- Certified Balancing of rotating parts

- PMI

- Third party inspection on request

- Running and Performance test where applicable

CONTACTS

Via Panzeri 6/A

23892 Bulciago (LC)

Italy

+39 335 7076519

sales@italfm.com